Warehouse Floor Repairs Melbourne

Industrial and showroom floors take a beating—forklift traffic, heavy loads, racking anchors and years of wear. We repair damaged warehouse and showroom floors across Melbourne: dynabolt holes, cracks, failed joints, settlement voids and surface deterioration. Lasting repairs that restore structural integrity.

What We Deliver

Warehouse Floor Repairs Scope

Specialist warehouse and showroom floor repair services across Melbourne. We fix dynabolt holes, cracks, damaged joints, settlement voids and surface deterioration—restoring your industrial or retail floor to full working condition. Whether you're addressing dilapidations for lease end or maintaining a working facility, our team delivers lasting repairs that meet structural and safety requirements.

Our experienced team delivers professional warehouse floor repairs services across Melbourne's commercial and industrial properties. We understand the importance of meeting lease obligations and landlord requirements, working efficiently to minimise disruption while achieving quality results.

Professional vs Patch Repairs

| General Contractors | Make Good Melbourne | |

|---|---|---|

| Dynabolt holes | Basic mortar patching that shrinks and cracks | Core drill, epoxy fill, grind flush to original surface |

| Crack repairs | Surface filling that doesn't address subsurface damage | Epoxy injection restores structural bond, flexible sealants for movement joints |

| Joint repairs | Generic caulking that fails under traffic | Edge rebuild, proper re-cutting, appropriate sealant selection |

| Slab issues | Overlay patches that don't address root cause | Polyurethane injection to stabilise voids and settlement |

| Equipment | Hand tools and standard concrete products | Industrial grinders, injection systems, diamond tooling |

| Outcome | Temporary fixes requiring repeat work | Lasting repairs that meet lease and operational requirements |

Dynabolt Hole Repairs

When pallet racking, machinery or equipment is removed, you're left with hundreds of anchor holes in your floor. We core drill out damaged concrete around dynabolt holes, fill with high-strength epoxy resin, and grind flush to restore a smooth, level surface. Essential for lease end make goods and floor re-coating.

Crack Repairs

Floor cracks compromise structural integrity and create trip hazards. We use epoxy injection to fill and bond cracked concrete from within, restoring load-bearing capacity. For wider cracks, we rout and seal with flexible polyurethane that accommodates movement. Surface cracks are ground out and filled flush for a seamless finish.

Joint Repairs

Control joints, construction joints and movement joints take the brunt of forklift traffic. Failed joints cause edge spalling, trip hazards and accelerated deterioration. We repair damaged joint edges with epoxy mortar, re-cut joints to proper depth, and install appropriate sealants—rigid for construction joints, flexible for movement joints.

Our Process

Floor Assessment

We inspect your floor to identify all damage: dynabolt holes, cracks, joint failures, settlement areas and surface deterioration.

Repair Specification

Based on damage type and your requirements (lease end vs operational), we specify appropriate repair methods and materials.

Repair Execution

Our team completes repairs using industrial equipment and professional-grade epoxy, polyurethane and cementitious systems.

Handover Ready

Completed repairs are ground flush and documented. Your floor is ready for inspection, coating or continued operations.

Slab Stabilisation

Settlement, voids and rocking slabs indicate problems beneath the surface. We inject polyurethane foam or cementitious grout to fill voids, stabilise settlement and re-level sunken sections. This non-invasive approach avoids costly slab replacement and restores load-bearing capacity across the affected area.

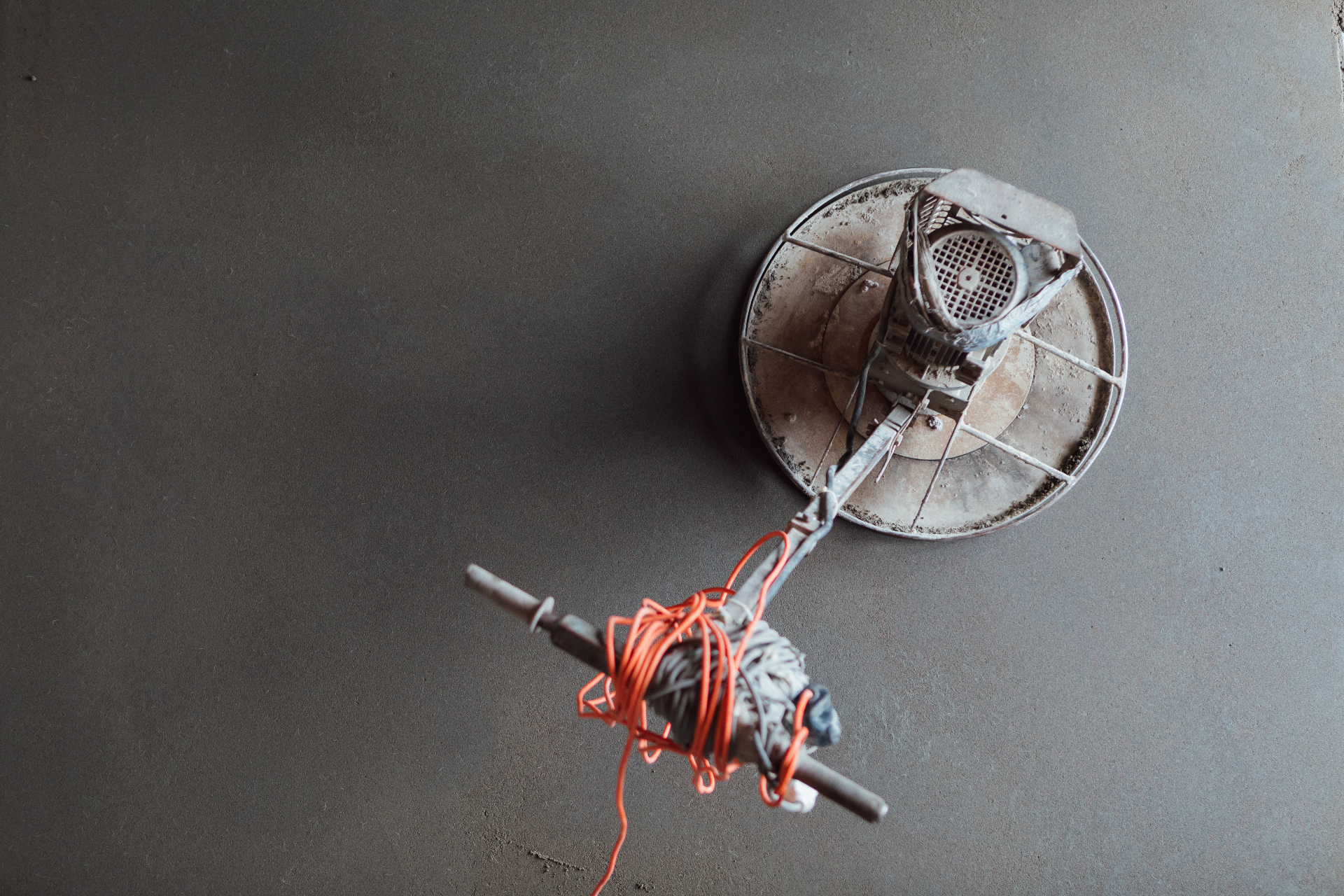

Floor Grinding & Levelling

Uneven floors, high spots and surface deterioration affect forklift operation and safety. Our industrial floor grinding equipment levels surfaces, removes coatings and prepares floors for epoxy systems or grind-and-seal finishes. We restore flatness tolerances required for efficient warehouse operations.

Frequently Asked Questions

Let Us Repair Your Warehouse Floor

We do makegoods all day, every day.

From dynabolt hole filling to slab stabilisation, we've repaired warehouse floors across Melbourne. Get in touch today for a free, no-obligation quote.

Related Services

Pallet Racking Removal

Racking bolted to your floor and walls? That's your landlord's problem now—unless you sort it before handover. We dismantle, remove and dispose of all racking systems, protection bollards and wall brackets, then core drill and fill those anchor holes so you get your bond back.

Learn more

Epoxy Flooring

Tired concrete floors dragging down your warehouse? Epoxy transforms worn, stained slabs into durable, professional surfaces that impress clients and stand up to forklifts, chemicals and heavy traffic. New installs or restoration—we handle it.

Learn more

Concrete Slab Restoration

End of lease and your concrete floor needs to be restored? We remove carpet, vinyl, tiles, adhesives and coatings—then grind and prepare the slab to handover-ready condition. Our advanced grinding equipment can fully ablate concrete surfaces, removing contamination that traditional floor grinding devices are unable to remove.

Learn more